In recent years, scientists have been in the process of finding alternative eco friendly refrigerants. One option that scientists are proving to be quite efficient are solid refrigerants.

Many scientists are optimistic that these refrigerant types might be the future of the refrigerant industry. In fact, there are a few new air conditioning systems in the market that are using solid-state refrigerants to heat and cool spaces.

But how exactly does this type of solid-state refrigerant function? How does it differ from liquid refrigerants? Will these refrigerants take over the refrigerant industry in a few years?

Our article discusses the concept behind this technology that has taken the refrigerant industry by storm. Read further to learn more about it.

How Solid Refrigerants Differ from Traditional Refrigerants

Conventionally, liquid refrigerants have been the go-to option for many heating and cooling applications. These refrigerants consist of a combination of different chemicals, such as hydrogen, fluorine, chlorine, and carbon. These fluids change from a liquid to a gaseous state when they absorb heat and transform back into a liquid when cooled.

For instance, in a traditional air conditioner, the refrigerant moves within a sealed system. It absorbs the heat in a room via the evaporator and changes to vapor as it comes into contact with heat. The hot refrigerant then moves into the compressor that compresses it to increase its temperature and pressure. It then moves to the condenser, which cools the refrigerant, release the heat, and converts it back into a liquid.

Solid refrigerants, on the other hand, achieve cooling by changing the microscopic structure of the refrigerant’s material when you apply a magnetic field, electricity, or mechanical force. In our research, we found three solid refrigeration technologies that use solid refrigerants at the time of writing this article (July 2023). In case I leave out any, feel free to contact us.

1. Cooling using barocaloric materials

Barocaloric materials use pressure changes, similar to compressor based refrigerants, when going through different heat cycles. However, these refrigerants remain in a solid state throughout the heat cycle even though the internal molecular structure changes.

But how is that even possible?

Barocaloric materials have a long, flexible molecular chain that are floppy and disorderly. When under pressure, they become rigid and orderly like shown in the image below. That change is what helps the refrigerant release heat.

In 2022, scientists from the Harvard University came up with a prototype cooling system meant to use solid-state Barocaloric materials to transfer heat. The prototype is a compressor free system that consists of three parts:

- A metal tube that contains the solid refrigerant and an inert liquid (water or oil)

- A Hydraulic piston, which is used to apply pressure to the liquid

- A liquid used to transfer the pressure to the refrigerant and carry heat through the system

Uses of barocaloric cooling:

- Alternative to vapor compression systems in AC units

- Heat pumps

Here’s a video explaining how scientists expect this concept to work:

2. Magnetic refrigeration

Magnetic cooling uses the magnetocaloric effect and is common for attaining low temperatures. When you pass a magnetocaloric material (which acts as the refrigerant in this case) such as gadolinium and dysprosium in a magnetic field, it warms up since it releases heat. When removed from the magnetic field, the material returns to its original state.

How do manufacturers use this concept to achieve refrigeration?

As the external magnetic field increases, the dipoles of the atoms align, causing the material to lose its magnetic entropy and heat capacity.

A fluid or a gas such as Helium then removes the heat from the material until it achieves sufficient cooling levels. The magnetic field remains constant at this point to prevent the material from reabsorbing heat.

After this, the material goes back to an insulated condition within a decreased magnetic field. The reduced magnetic field allows the thermal energy to overcome the magnetic field through a process known as adiabatic demagnetization; hence, achieving the cooling effect.

The diagram below compares the magnetic refrigeration to the vapor cycle refrigeration.

Source: Wikipedia

Common cooling devices that use magnetic cooling include:

- Commercial and domestic fridges

- Beverage coolers

- Heat pumps

3. Thermoelectric cooling

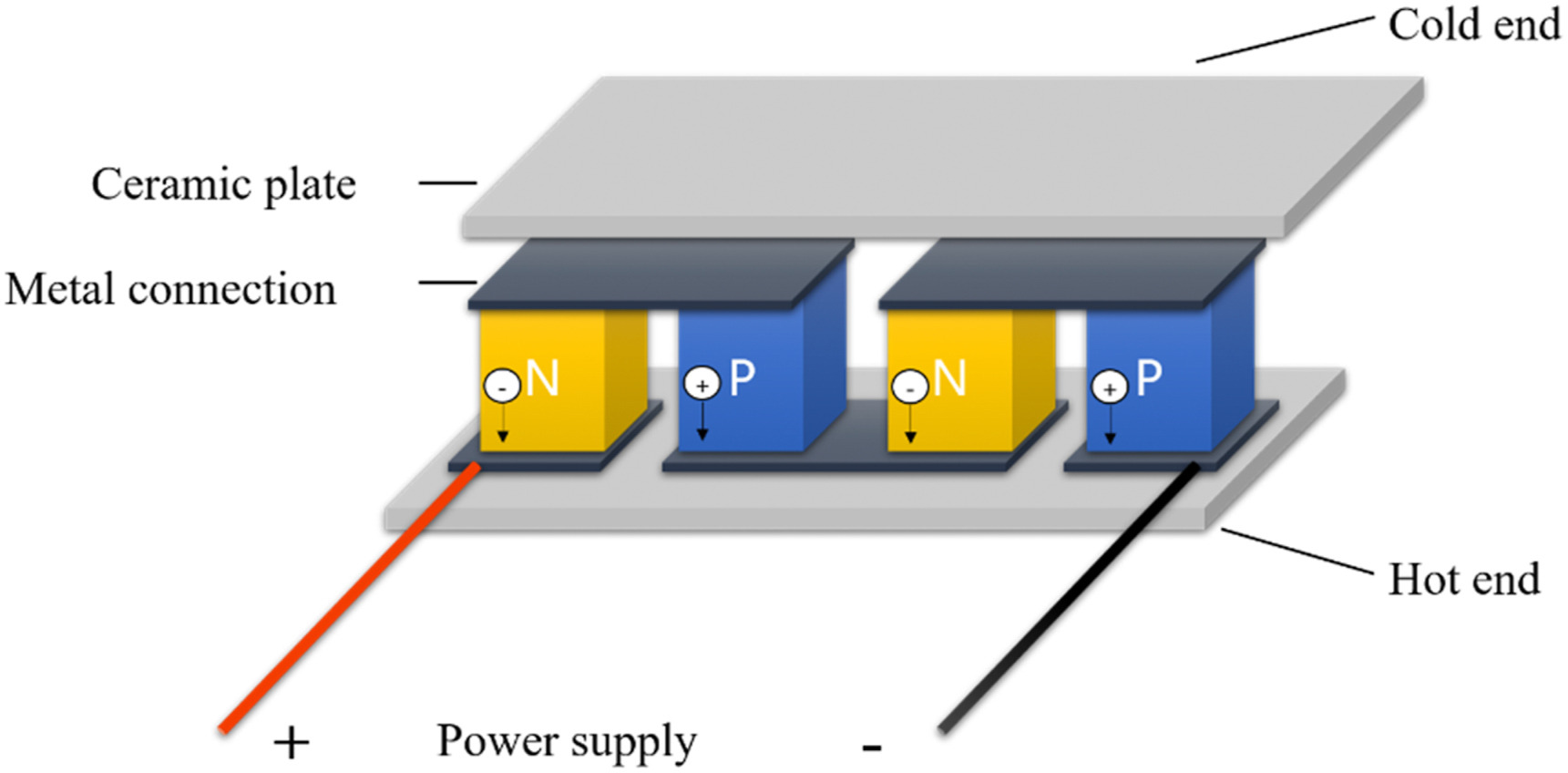

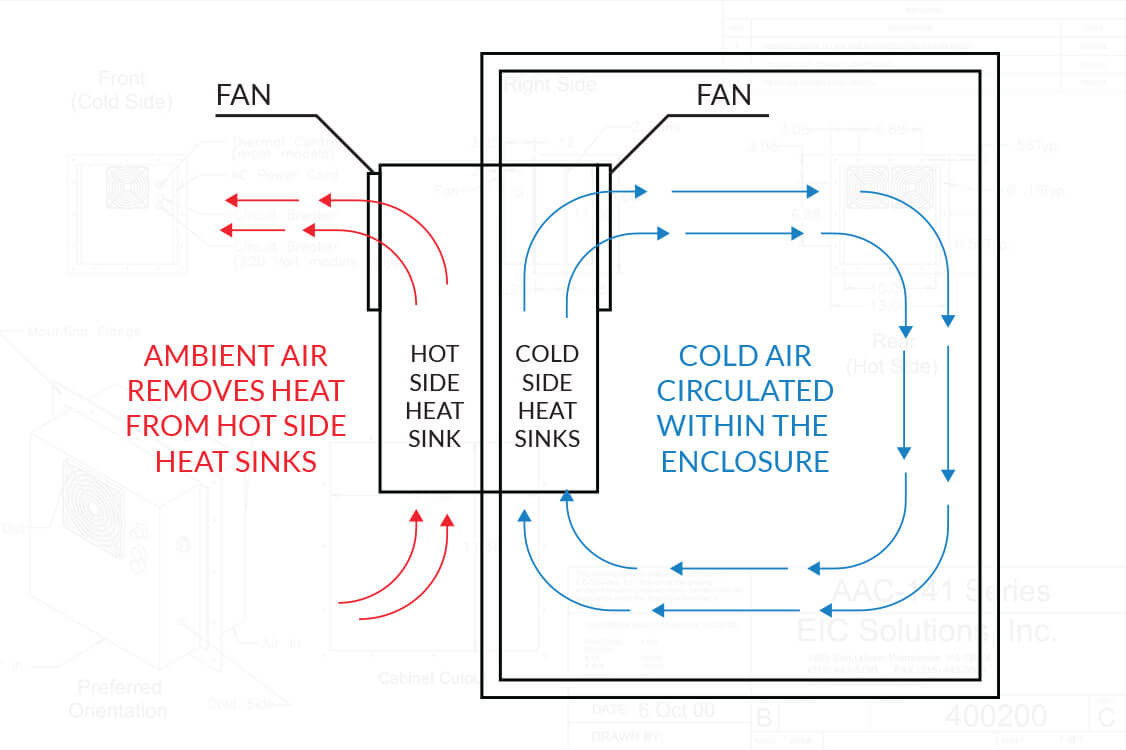

The concept uses electricity to create a cooling effect. These systems have two conductors such as copper and zinc (which acts as the refrigerant in this case) placed next to each other and a metal connection. When you pass direct current on the two conductors, a temperature change occurs at the connection.

Normally, the system will have two sides: a hot side and a cooler side. The cold side goes into the machine while the hot side is usually on the external side. The hot side will help to remove excess heat. To apply this concept on large devices, manufacturers have to increase the effect by adding more metal connections.

Thermoelectric cooling is common in cooling appliances such as:

- Ice-free coolers

- Wine refrigerator

The image below explains how thermoelectric cooling works.

Image Source: Department of Energy

Benefits of Solid Refrigerants

Now that we have a basic idea of the three types of solid refrigerants being tested right now, how will these concepts benefit the refrigerant industry? Why is there a high chance of these refrigerants taking over the market in a few years to come?

1. They are not toxic to the environment

One of the reasons why there are multiple regulations such as the Kigali Amendment on liquid refrigerants is their impact on the environment. During installation, repair, or maintenance, some of the refrigerant might sneak into the atmosphere. Huge amounts cause significant global warming, especially if you are using refrigerants such as HFCs and HFOs that contain fluorine.

This is not the case with solid refrigerants. Since scientists are looking for suitable replacements for these gases, solid refrigerants might be an ideal option because there are no chemicals used in creating these refrigerants.

2. Solid refrigerants are energy efficient

Many people nowadays invest in HVAC systems because the earth is getting warmer by the day. According to the Department of Energy, air conditioners use 6% of all the electricity produced in the United States alone. That means that heating and cooling systems, especially the ones that use compressors might use a lot of electricity to function properly.

However, this is not the case with solid refrigerants. For instance, thermoelectric coolers are small. They don’t use a lot of electricity like compressor-based coolers. Scientists also predict that magnetic cooling has the potential of saving 30% of the energy consumed when using conventional refrigeration methods.

In addition to this, scientists believe that that cooling systems that use solid refrigerants might save a lot of energy since they rely on small pressure change to remove a large amount of heat; hence, the reason it outperforms vapor compression.

Limitations of Solid State Refrigeration

Although solid refrigerants are efficient and not toxic to the environment, they are still far from being perfect because most of these concepts are still on the developmental stages.

One of the significant challenge companies might face when producing products that use solid refrigerant is cost.

For instance, the prototype device created by the Harvard students may be expensive to produce at the moment because the specialized equipment needed to develop an efficient system could be a bit costly. Meaning, consumers might have to dig deep to invest in such a device.

It’s also the same issue with thermoelectric cooling. The cost increases, especially if you have to create a system to use in a large space.

Other notable challenges that the industry needs to overcome are:

- Magnetic refrigeration materials are scarce

- Barocaloric systems require massive pressure to drive heat cycles

- Thermoelectric cooling might not be suitable for creating dehumidifiers since it cannot heat the air around them.

Conclusion

As you can see in this article, solid-state refrigeration might be a viable option for the future, especially if we cannot find eco-friendly refrigerants. They are efficient, less toxic, and have the same result as when you use liquid refrigerants. Thanks for reading our article and good luck.